sprintBOX: Ihr All-in-One Partner für KLT-Behälterreinigung, Behältervermietung & externe Lagerung von Ladungsträgern

Ihr Vertrauen in unsere Leistungen

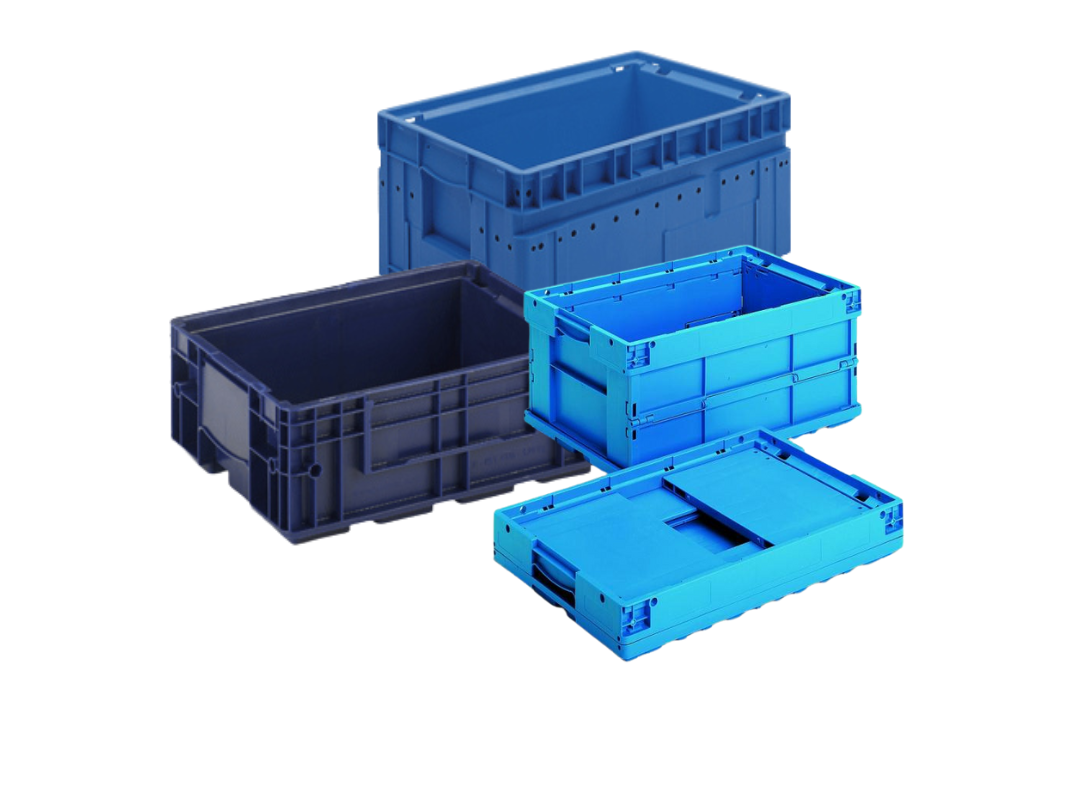

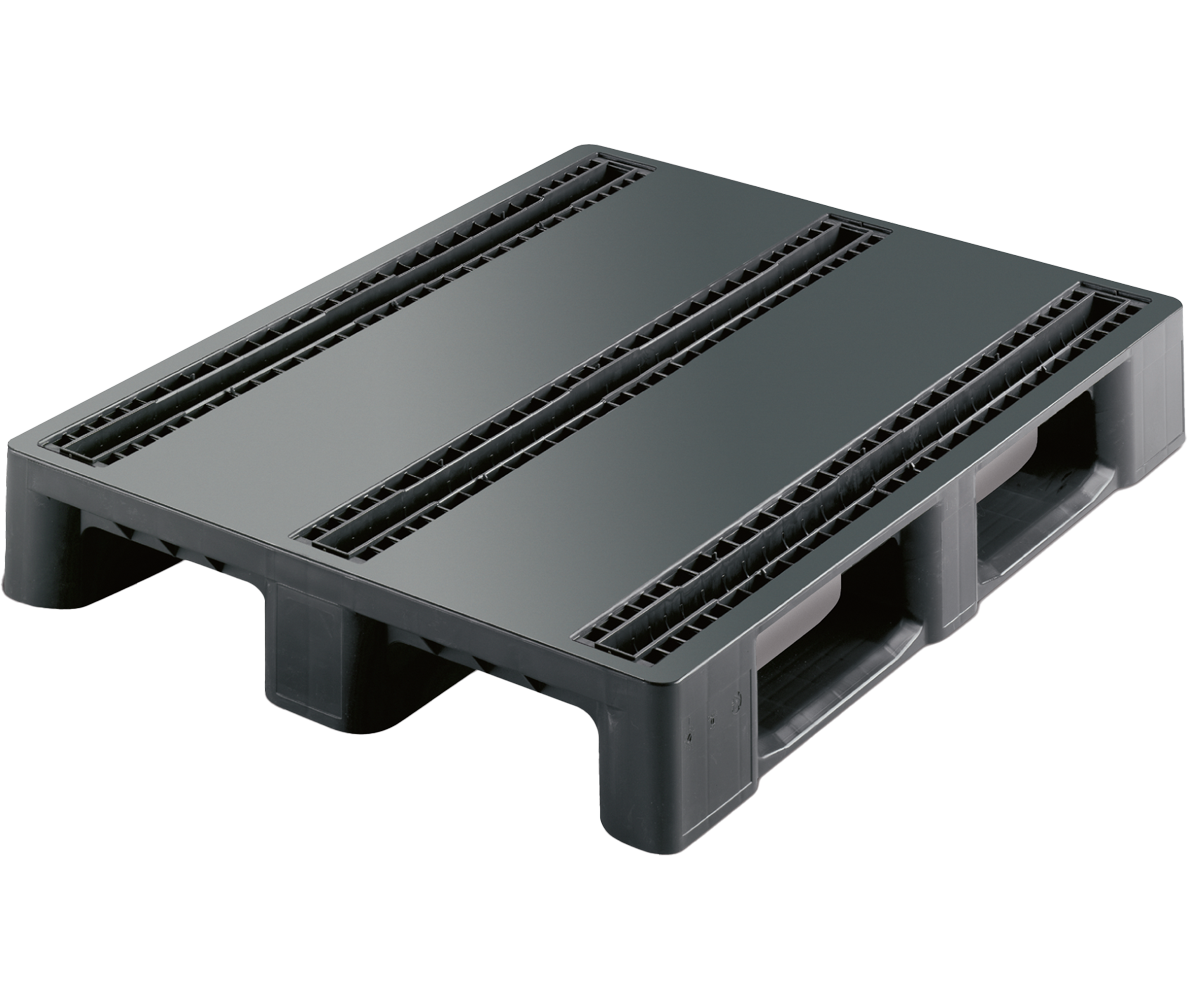

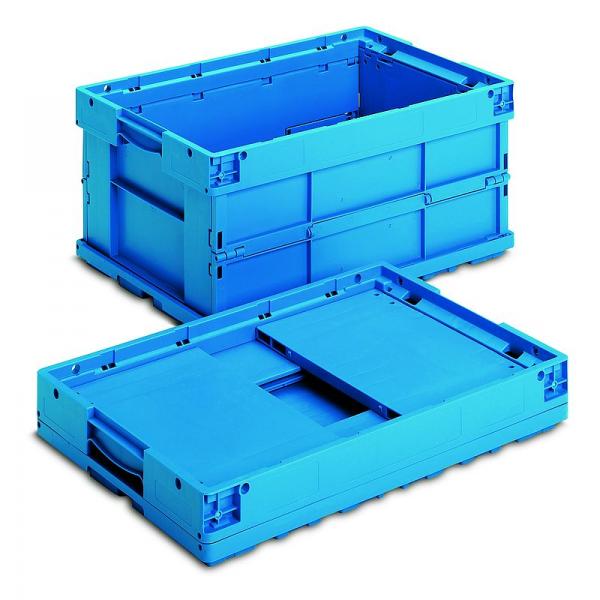

Ihre Wunschbehälter zur Miete.

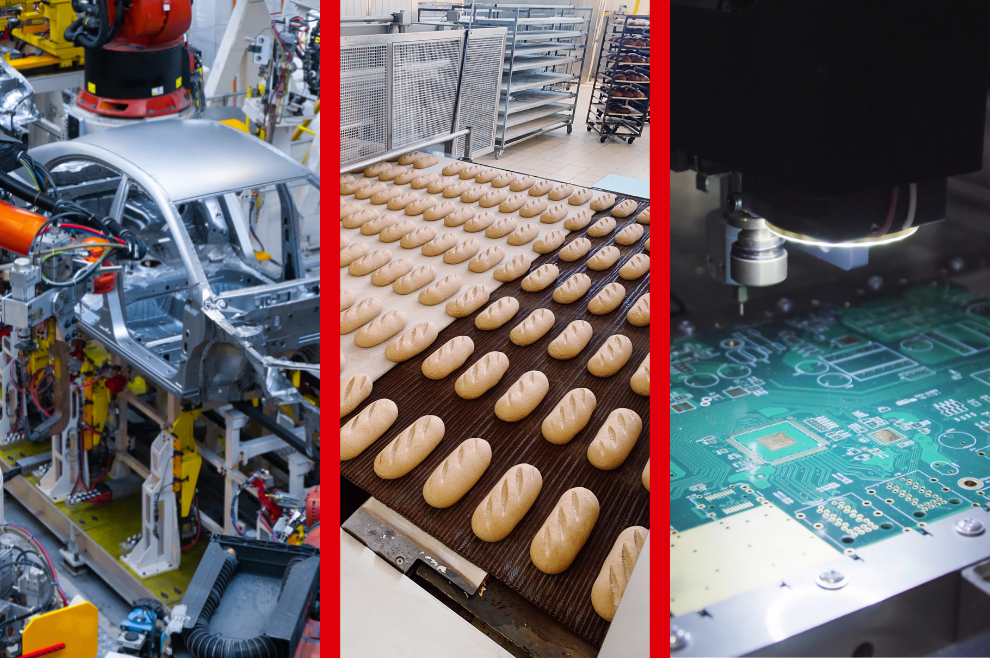

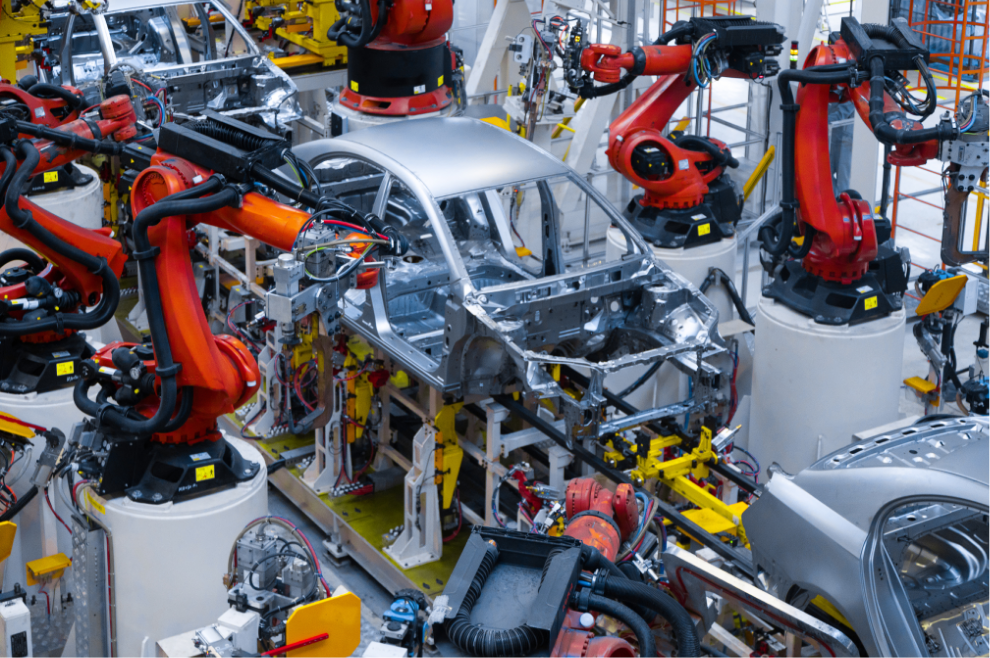

Wir sind der perfekte Partner für Unternehmenslösungen und die Versorgung Ihres Transport-Kreislaufs.

Effizientes Behältermanagement

in ganz Europa schnell, verlässlich und kostengünstig – sprintBOX ist Ihr bevorzugter Partner in der Beschaffung und Reinigung von Behältern.

Immer für Sie erreichbar

Schnelle, kompetente und direkte Beratung durch unser Serviceteam.

Ihre Wunschbehälter zur Miete.

Wir sind der perfekte Partner für Unternehmenslösungen und die Versorgung Ihres Transport-Kreislaufs.

Effizientes Behältermanagement

in ganz Europa schnell, verlässlich und kostengünstig – sprintBOX ist Ihr bevorzugter Partner in der Beschaffung und Reinigung von Behältern.

Immer für Sie erreichbar

Schnelle, kompetente und direkte Beratung durch unser Serviceteam.

sprintBOX Blog

Und was können wir für Sie tun?

Sofortanfrage: